The Printed Circuit Boards (PCBs) are very sophisticated and complicated items which are of utmost importance in the smooth operation and sustainability of the electronic machinery and it would not be an overstatement to say that even the slightest of faults in a PCB can bring the working of fundamental machinery to a standstill. In this scenario, it is of vital to have approved standards of quality control for the manufacturing, development, and operation of the Printed Circuit Boards (PCBs). Some of the standard tests performed in order to ensure the quality of the Printed Circuit Boards (PCBs) are as follows,

- 100% Electrical Test

- 100% Visual Inspection

- Dimensional Inspection

- Micro Section

- Solder Ability Test (245+-5C), 10 sec

- Thermal Test (288+-5C)

- Tape Test

- Peel Test

- Impedance Test

- Ionic Contamination Test

All these tests are performed during the process of PCB manufacturing and assembly at SynergisePCB Inc. Looking into the details of all the tests, we can take them in sequence.

1) 100% Electrical Test

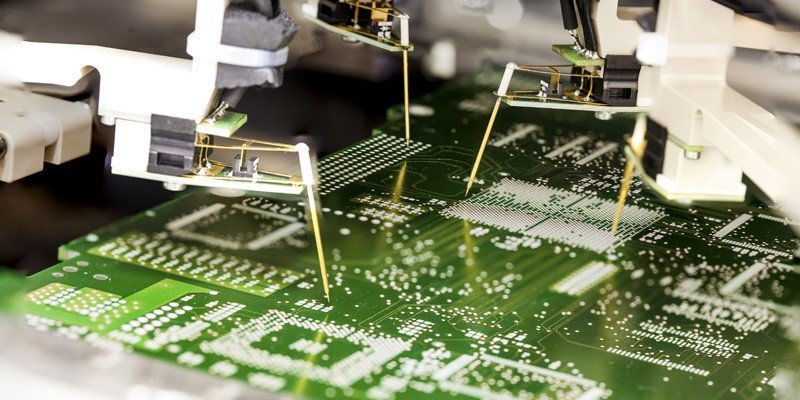

Electrical testing is of utmost importance for a PCB which involves the electrical testing of various aspects of the Printed Circuit Boards (PCBs). In electrical testing, every “Node” on the PCB board is tested. Short circuit tests are performed to be if any part of the PCB is short-circuited. Clamshell tests are performed to obtain the simultaneous testing of both sides of the PCB in case of double-sided Printed Circuit Boards (PCBs).

Continuity tests are performed to check if the resistance between the tests points is within the specified limit. Some of the other tests performed in the Electrical testing of the Printed Circuit Boards (PCBs) are the flip test, high pot test, impedance control test, leakage test, opens test and optimized netlist tests.

2) 100% Visual Inspection

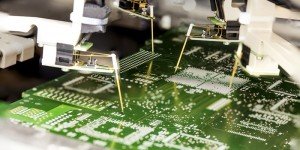

Visual tests are performed using AOI machines to check if all the components after the Printed Circuit Boards (PCBs) assembly process are there where they are supposed to be. The AOI machines use high-resolution cameras aided with software Gerber and drill files to make the comparison of the Printed Circuit Boards (PCBs).

3) Dimensional Inspection

Dimensional inspection is necessary because the size and dimension of the Printed Circuit Boards (PCBs) are specified as per the design of the device in which the PCB has to be used in. The dimensional test compares the physical dimensions of the PCB against the software provided the design of the PCB.

4) Micro Section Testing

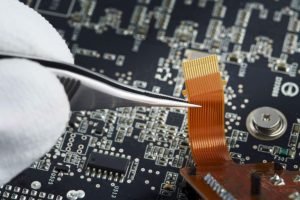

The micro testing of the Printed Circuit Boards (PCBs) is performed in order to check the drill via on the PCB. Via is micro sized in PCB and has to be carved with the greatest care as a slight offset in via can be of serious design and operation faults. This is why micro tests are given high priority during PCB development at SynergisePCB Inc.

5) Solder Ability Test

It is our understanding that components are soldered on the PCB during the Printed Circuit Boards (PCBs) assembly process, therefore, it is necessary to check the durability of the solder through the solderability test. The solder has to withstand high temperatures and extreme working conditions without showing any signs of deterioration. The solder tests are performed up to 245C for 3 seconds to check the response of the solder. If the ability to withstand such conditions, only then it passes the solderability test.

6) Thermal Ability Test

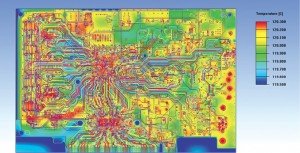

During the working of Printed Circuit Boards (PCBs), extreme conditions can arise which can lead to heating of the inner core. In such cases, the Printed Circuit Boards (PCBs) should be able to withstand the extreme heating. Thermal ability tests are performed by subjecting it to temperatures up to 288 for about 10 seconds to check its performance.

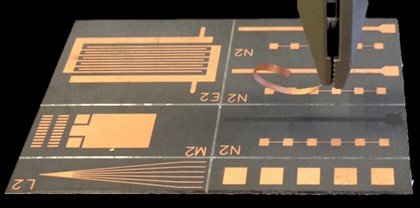

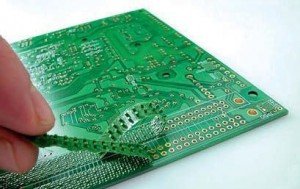

7) Tape Test (adhesion test)

Tape tests are performed to check the adherence of the copper foil on the PCB. The tape is applied to the Printed Circuit Boards (PCBs) and peeled off in order to check if any copper foil residue adhered to the tape. The Printed Circuit Boards (PCBs) is only passed for further processing if no copper residue adheres to the tape.

8) Impedance Test

Impedance testing is done in order to check the impedance between different nodes and the components of the Printed Circuit Boards (PCBs). The impedance should not be offset to the specified limits.

9) Ionic Contamination Test

The Printed Circuit Boards (PCBs) during manufacturing and developing process can be contaminated with ionic impurities which can lead to the decrease in the impedance of the Printed Circuit Boards (PCBs) which can cause operational ambiguities. In order to avoid any unforeseen circumstances, the ionic contamination tests are performed.

At SynergisePCB Inc. we deeply care about the quality control and operational efficiency and reliability of our manufactured Printed Circuit Boards (PCBs) and give extreme importance to all the approved standard tests.