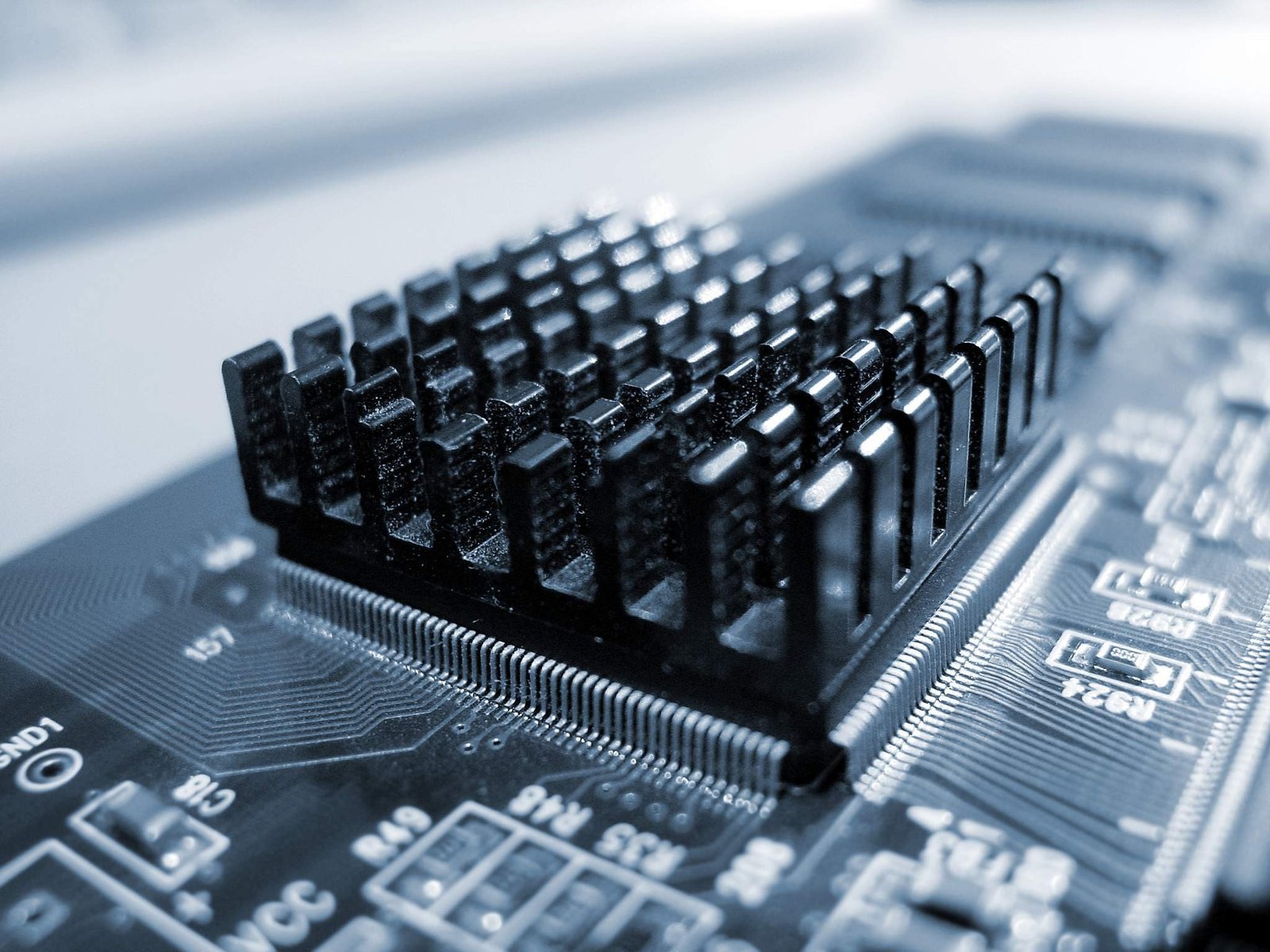

Printed Circuit Board Material & Types of SMDs

Specially professional of Printed Circuit Board Material like Hdi To 3+, Stacked Micro Vias, Copper Filled, Blind/Buried Vias, Sequential Lamination, Via‐in‐pad, Conductive Or Non‐conductive Fill, Special Materials, Hybrid Constructions, Metal Back Pcb And Heat Sinks, Heavy Copper Up To 6 Oz

Surface Mount Devices (SMDs) are similar in function than their Thru-Hole counter parts. The only difference is how they are assembled to the PCB circuit board. SMDs are mounted on the circuit board while the Thru-Hole components are connected by their end leads. Since SMDs are smaller and occupy less volume in a circuit board therefore they are better in performance when it comes to the PCB circuit board. But not all the components are available in SMDs so we have to use the mix components.

Types:

Passive SMDs: The big advantage of these types of components is that they much light in weight. On roughly estimation, they are ten times lighter than the Thru-Hole components used in PCB circuit board. They are available in rectangular and cylindrical shapes.

Surface Mount Discrete Resistors: They are available in various power rating and resistance values. They have further two types: thick film and thin film resistors.

Ceramic Capacitors: They are best suited for the high frequency circuit applications since it does not contain any external leads to be connected on a PCB circuit board. They are widely used for the decoupling applications and frequency control.

Tantalum Capacitors: Another type is the Tantalum capacitor. The difference is in the dielectric. Here, the dielectric used is Tantalum. They give very high volumetric efficiency and high capacitance-voltage product per unit volume and high reliability. The best thing about these types of capacitors is that they are available in different sizes. Moreover; you can design the customized capacitor based on your PCB circuit board design.