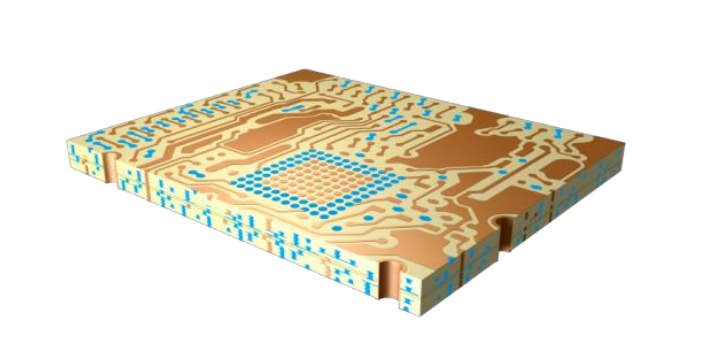

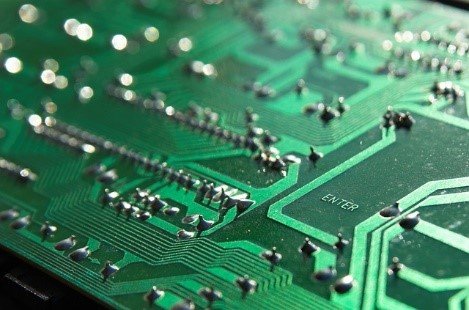

The outermost layer of copper on a Printed Circuit Board is known as the solder mask layer. This layer provides the PCB its green or sometimes red colour. It is coated on the copper foil to insulate and the traces of copper from unintentionally getting in touch with other metal or equipment parts, solder on the Printed Circuit Board, or current conduction paths. This outermost layer allows soldering at the appropriate places on the Printed Circuit Board and discourages solder jumpers.

Green Solder Mask

Solder mask is usually green in color but sometimes other colors are also possible. Red is another color for solder mask that is commonly used by the Printed Circuit Board manufacturers.

A white colored silkscreen layer is coated on top of the solder mask coating of the Printed Circuit Board. Silkscreen is usually white in color but other colors such as black, red, gray, and yellow are also commonly available for the purpose. However, only a single color is used for the purpose of inscribing letters and symbols since more than one color may not look good. The silkscreen is mostly used for inscribing letters, symbols, and numbers, on top of the Printed Circuit Board. This makes assembly and indicators of the Printed Circuit Board more easy and convenient for everyone involved to understand. Synergise PCB also uses silkscreen indicators to reflect the working and function of almost every pin or LED on the Printed Circuit Board.