There are a lot of Terminologies that you may encounter while dealing with Printed Circuit Boards. Some of those terminologies are as following:

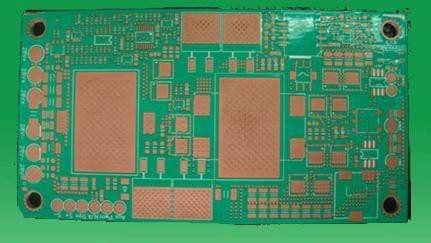

Annular ring: This is a copper ring around a plated through hole in a Printed Circuit Board.

There are different types of Annnular rings. Some of the popular examples of annular rings are as follows:

- Resistor Annular ring

- Vias Annular ring

DRC – design rule check: It is a software based check of PCB design to ensure the design is free of errors like traces that incorrectly meet or cut, skinny traces, or small drill holes.

Drill hit: Places on boards where there is a need to drill hole, or where they exist on the board. Inaccurate drilling due to dull bits are a pretty common in manufacturing.

Finger: These are metal pads exposed at the edge of a board, and they make a connection between two boards. Popular examples holes at the edges of computer expansion or memory boards.

Mouse bites: These are a replacement to v-score and they are used to separate boards and panels. There are a number of different drill hits while come close together to each other. Thet result in a weak spot. This wat the board gets broken easily.

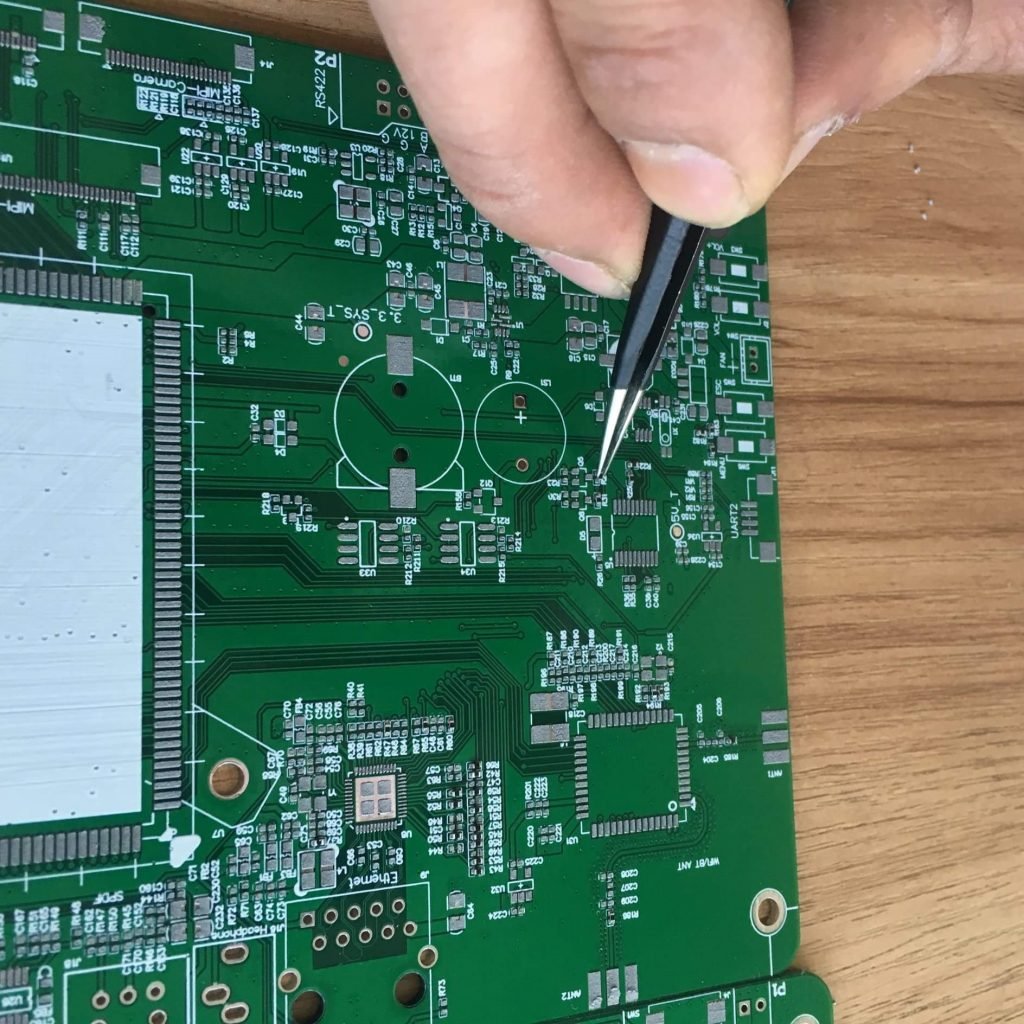

Pad: This is a portion of metal which is exposed on the board surface and a component is soldered to this part.

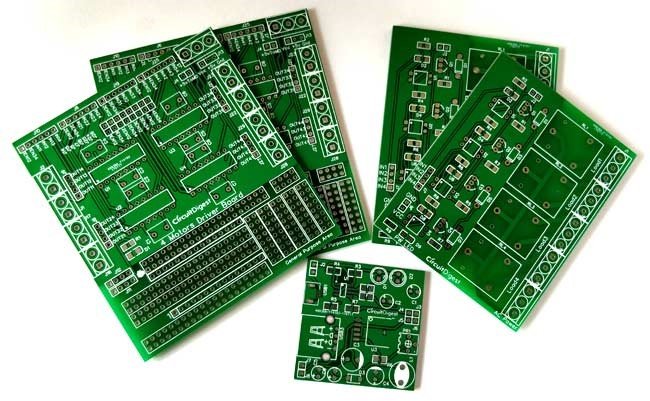

Panel: This is a big printed circuit board having many smaller boards. They will be separated before they are used. An Automated printed circuit board handling equipment may have troubles with smaller printed circuit boards. They can aggregate many printed circuit boards at once which will speed up the process significantly.

Paste stencil: This is a thin, metal stencil that lies is placed over the board. This allows the solder paste on specific areas during the printed circuit board assembly process.

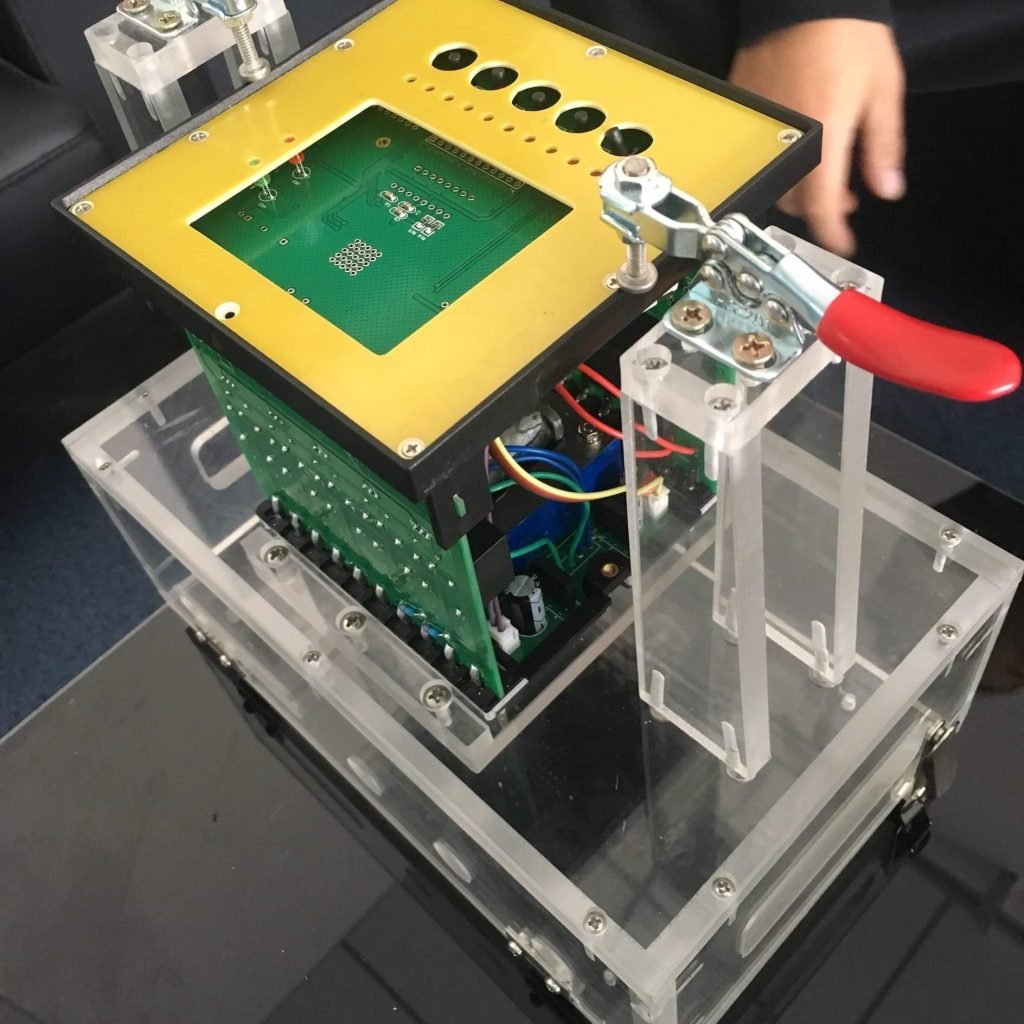

Pick-and-place: This term is used for the machine or the specific process in which the components are picked and placed on the surface of the printed circuit board.

Plane: This is a running block of copper on a printed circuit board. It is also popularly known as “pour”.

PCB ground pour: This term is used for PCB portions, which have no traces but they have a ground pour.

Plated through hole: There are different types of holes on the surface of Printed Cicuit Board and it is one of them. It makes a connection for a through via to pass a signal through the equipment from the printed circuit board.

Plated through Hole resistor: This is a resistor, which is inserted into the PCB. The legs of the PTH resistor are inserted in the holes. The plated holes have traces joining them to the front and the rear side of the PCB.

Pogo Pin: It is a spring-loaded joint for making a temporary connection during testing or programming operations.

Reflow: This term is used during melting the solder for making connections between pads and component leads on the Printed Circuit Boards.

Silkscreen: This term is used for the number, symbols, letters, and imagery on a printed circuit board.